Enter RSJ

Founded in 2001, RSJ Group has over two decades of experience driving innovation and excellence in the stamping foil industry. Guided by the core values of customer first and shared success, RSJ has strategically established offices in Hong Kong, Shenzhen, and Foshan, leveraging both local industrial ecosystems and international resources. This integrated approach has enabled the Group to build a global innovation network, continuously pushing the boundaries of stamping foil technology.

RSJ operates three specialized subsidiaries—Golden Laser, Shunneng Chemical Tech, and PSTM (Promising Surface Technology Management Co., Ltd.)—each dedicated to advancing different aspects of the stamping foil industry. Golden Laser focuses on the R&D, production, and sales of premium stamping foil, serving as a core driving force in the industry chain. Shunneng Chemical Tech pioneers green coating technologies, achieving fully water-based coatings for all stamping foil processes and leading the market in high-performance coating solutions. PSTM specializes in precision stamping foil materials, developing next-generation products and customized solutions that strengthen RSJ’s position as a comprehensive provider of stamping foil solutions worldwide.

By combining cutting-edge technology, deep industry insight, and exceptional product quality, RSJ has earned widespread recognition and established a strong, trusted reputation across the global market. Today, RSJ is widely regarded as an industry innovator, a benchmark for quality and reliability, and a trusted partner for companies worldwide seeking advanced stamping foil solutions.

RSJ operates three specialized subsidiaries—Golden Laser, Shunneng Chemical Tech, and PSTM (Promising Surface Technology Management Co., Ltd.)—each dedicated to advancing different aspects of the stamping foil industry. Golden Laser focuses on the R&D, production, and sales of premium stamping foil, serving as a core driving force in the industry chain. Shunneng Chemical Tech pioneers green coating technologies, achieving fully water-based coatings for all stamping foil processes and leading the market in high-performance coating solutions. PSTM specializes in precision stamping foil materials, developing next-generation products and customized solutions that strengthen RSJ’s position as a comprehensive provider of stamping foil solutions worldwide.

By combining cutting-edge technology, deep industry insight, and exceptional product quality, RSJ has earned widespread recognition and established a strong, trusted reputation across the global market. Today, RSJ is widely regarded as an industry innovator, a benchmark for quality and reliability, and a trusted partner for companies worldwide seeking advanced stamping foil solutions.

Originator

Ron Li

CEO

Ron Li is the founder of RSJ Group and has over 38 years of experience in the stamping foil industry. Early in his career, he went to Japan to study stamping foil production techniques, and later to Germany to deepen his knowledge of foil formulation processes and production equipment. Through continuous improvement and innovation, he developed fully water-based formulations for stamping foil, covering the release layer, color layer, and adhesive layer, achieving a truly environmentally friendly stamping foil production process.

His developed formulations and processes significantly increase production efficiency, enabling all production stages to reach speeds of over 300 meters per minute, saving considerable labor and resources. The innovations also enhance product quality: release films have stable tension, high transparency, bright color layers, excellent slitting performance, high temperature resistance, wide stamping range, strong adhesion, and superior cuttability.

Currently, the market widely uses products such as standard stamping foil, laser stamping foil, holographic security foil, cold stamping foil, hard and soft plastic stamping foil, high-temperature laser stamping foil (over 230℃), transfer foil, and composite foil. These products are extensively applied to paper, cigarette packs, alcohol packaging, home appliances, cosmetics, tickets, ID cards, and consumer goods labels.

His developed formulations and processes significantly increase production efficiency, enabling all production stages to reach speeds of over 300 meters per minute, saving considerable labor and resources. The innovations also enhance product quality: release films have stable tension, high transparency, bright color layers, excellent slitting performance, high temperature resistance, wide stamping range, strong adhesion, and superior cuttability.

Currently, the market widely uses products such as standard stamping foil, laser stamping foil, holographic security foil, cold stamping foil, hard and soft plastic stamping foil, high-temperature laser stamping foil (over 230℃), transfer foil, and composite foil. These products are extensively applied to paper, cigarette packs, alcohol packaging, home appliances, cosmetics, tickets, ID cards, and consumer goods labels.

-

Golden Laser Technology 01

It is a high-tech enterprise specializing in aluminum electroplatiing.Dedicated to the R&D, production, and sales of premium stamping foil, Golden Laser is a core driver in the stamping foil industry. Products include hot stamping films for paper, holographic laser films, eco-friendly cold stamping films, platinum embossed films, and foils for plastics.

Guided by professionalism, quality, innovation, and efficiency, Golden Laser treats quality as its lifeline, combining lean production, continuous improvement, and customer satisfaction. Its modern facility spans over 30 acres, equipped with full precision production lines, R&D, testing, and lab centers, with an annual output exceeding 1.5 million standard rolls, ensuring both high quality and efficiency.

-

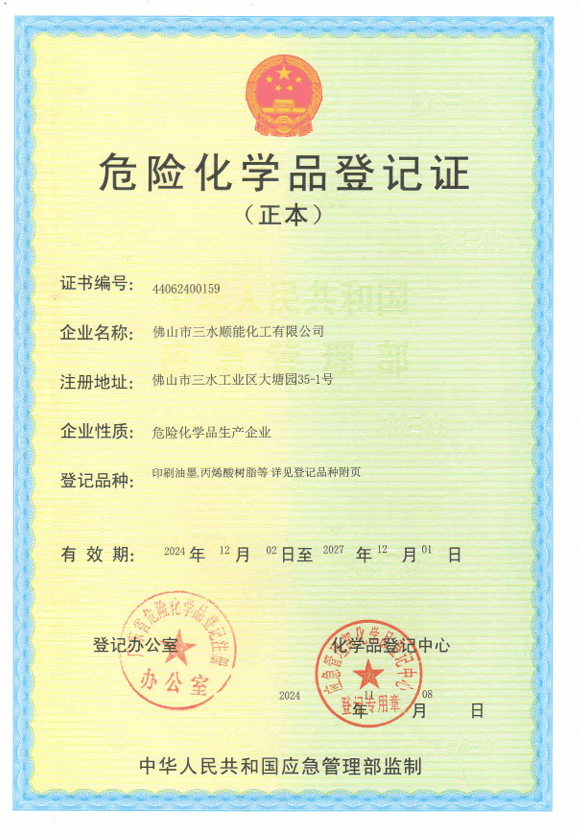

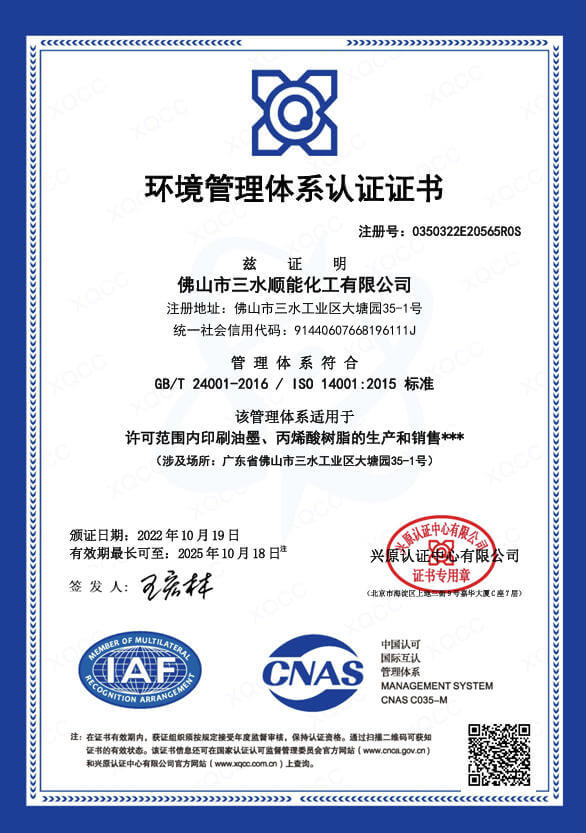

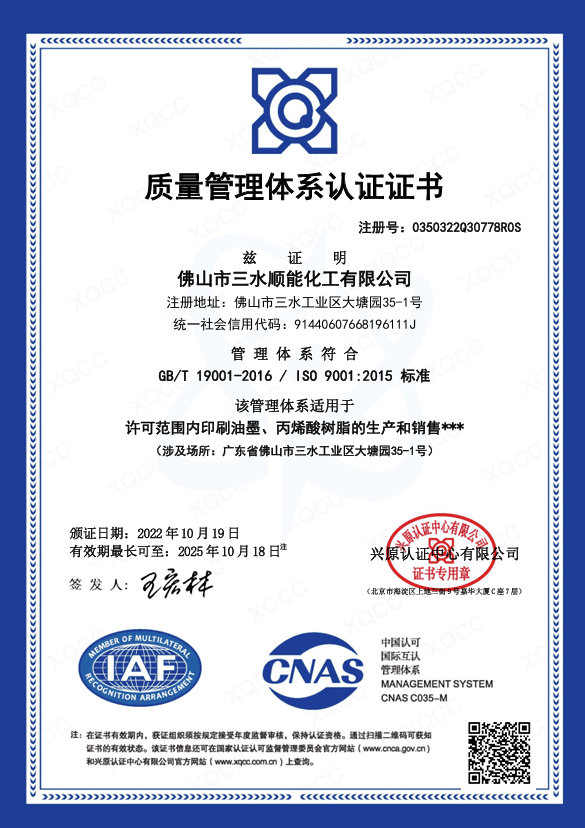

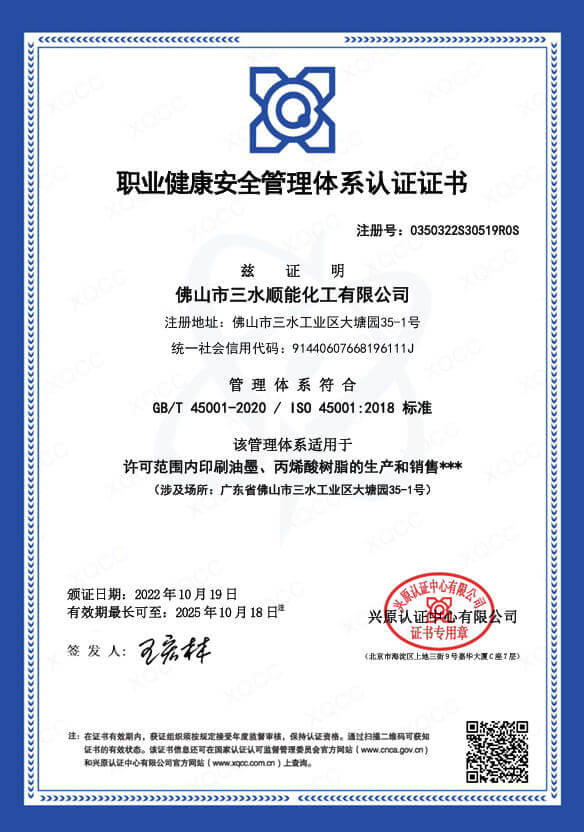

Shunneng Chemical Tech 02

A pioneer in green coating technologies, Shunneng Chemical Tech specializes in innovative stamping foil coatings and high-performance solutions.Its product range includes solvent-based and eco-friendly water-based coatings for standard and holographic stamping foils.

Shunneng’s coatings are widely used in cigarette packs, paper stamping, cold stamping, consumer goods, leather, textiles, and transfer/composite foils. Its fully water-based coating technology reduces environmental impact while driving sustainable growth in the stamping foil industry.

-

PSTM 03

Promising Surface Technology Management Co., Ltd.Focusing on high-precision photolithography technology, PSTM has top-tier capabilities in independently developing complex, high-precision anti-counterfeiting patterns. Equipped with accurate UV imposition systems and fully automated high-precision electroforming production lines, it meets the industry’s highest standards for formats up to 1.8 meters. With an annual production capacity of 100,000 sheets, PSTM provides a solid foundation for the precise and exquisite presentation of stamping foil effects.

Honorary Certification

University-Industry Cooperation